Image Source: ChatGPT

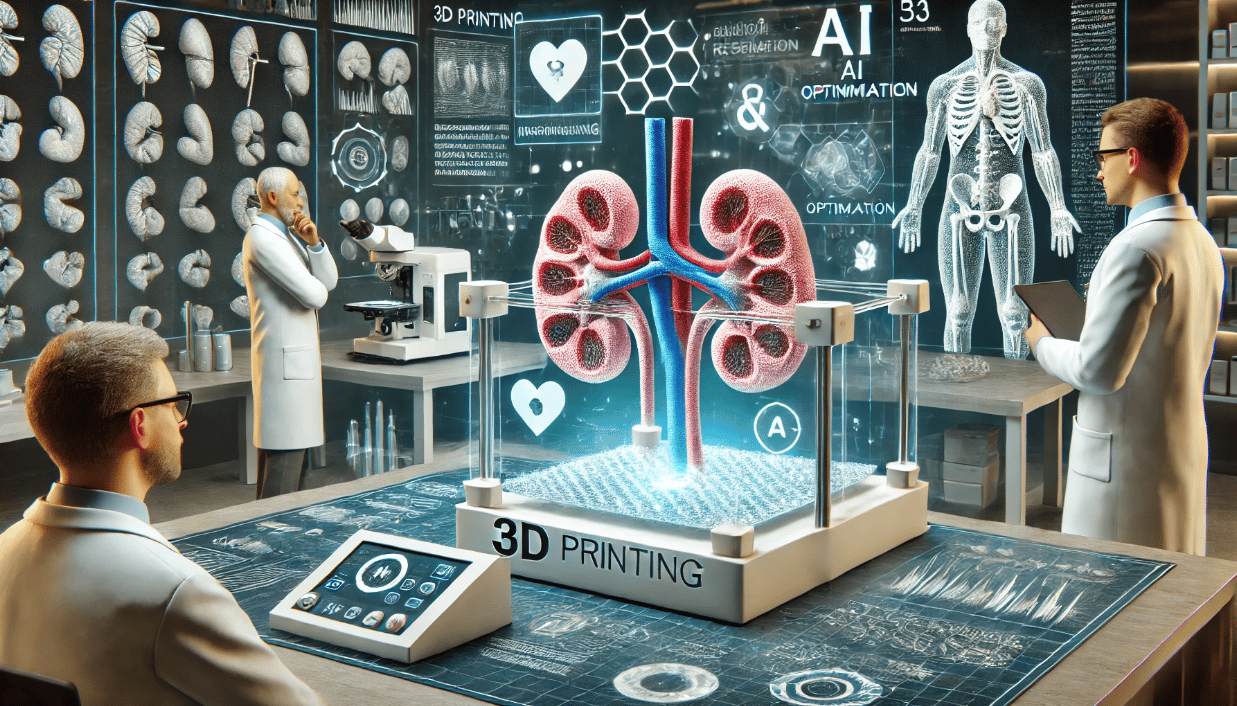

AI-Enhanced 3D Printing Boosts Efficiency in Organ Models

Researchers at Washington State University (WSU) have developed an artificial intelligence (AI) algorithm that significantly improves the efficiency of 3D printing, especially for complex structures. Published in the journal Advanced Materials Technologies, this breakthrough could pave the way for more effective use of 3D printing in creating everything from artificial organs to wearable biosensors and flexible electronics.

AI-Driven Optimization for Complex Designs

The AI algorithm developed during the study learned to identify and print optimal versions of intricate designs, such as kidney and prostate organ models. Over the course of the research, the algorithm produced 60 progressively refined versions of these models, optimizing the results to save time, cost, and labor. This advancement could streamline 3D printing processes, particularly for complex biomedical applications.

Addressing the Challenges of 3D Printing

While 3D printing has revolutionized the ability to rapidly convert digital designs into physical products, the process remains challenging. Engineers face numerous decisions about materials, printer configurations, and nozzle pressures, all of which influence the final product. The sheer number of possible combinations can be overwhelming, leading to inefficiencies and increased costs in trial-and-error approaches.

Advancing 3D-Printed Organ Models

For years, researchers have been developing lifelike 3D-printed organ models that replicate the mechanical and physical properties of real organs. These models are essential for applications like surgical training and implant testing, where accuracy and realism are crucial.

AI Technique: Bayesian Optimization

To improve the efficiency of 3D printing, the team employed Bayesian Optimization, a method that allowed them to refine key objectives for their organ models, such as geometric precision, weight (or porosity), and printing time. Porosity, in particular, is important for surgical practice, as it affects the mechanical properties of the model depending on its density. The AI model successfully balanced these objectives, leading to high-quality prints regardless of the material or shape.

Interdisciplinary Collaboration for Optimal Results

The project drew on expertise from multiple disciplines, resulting in a well-rounded approach to problem-solving. The balanced consideration of all objectives contributed to the project’s success, demonstrating the value of interdisciplinary research in creating impactful, real-world solutions.

Broader Applications and Future Potential

Initially, the researchers trained their AI model to print a surgical rehearsal model of a prostate. Thanks to the algorithm's versatility, it could be easily adapted to print a kidney model with only minor adjustments. This adaptability suggests that the method could be extended to other complex biomedical devices and potentially even other fields beyond biomedicine.

Support and Funding

This research was supported by the National Science Foundation, WSU Startup, and Cougar Cage Funds.